Don't confuse TPMS relearn with sensor programming.

Servicing TPMS equipped vehicles profitably can be a challenge without the knowledge, the right parts and the right tools. In spite of all the training programs and technical articles on the subject, there is still a lot of misunderstanding about TPMS, and the confusion between vehicle relearn and sensor programming tops the list. Vehicle relearn and sensor programming are completely different procedures. The issue stems from the availability of aftermarket TPMS sensors that come as “programmable”, “universal”, or “cloneable” sensor units. These sensors must be programmed with the proper protocol/application information for the vehicle before they can be installed in the tire, and then must be relearned to the vehicle. Unfortunately, some shops overlook the necessary relearn step mistakenly believing the sensor programming did the trick. This misconception can lead to service comebacks and customer complaints.

Here are the facts:

Vehicle relearn is a standard TPMS service step

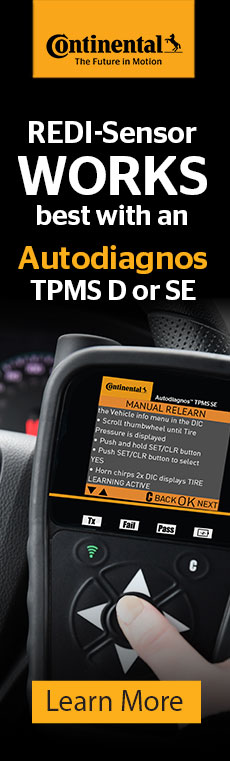

Every replacement TPMS sensor must be “relearned” to the vehicle following the prescribed OE relearn procedure, regardless of whether it is an OE or aftermarket sensor. The relearn procedure ensures not only that the replacement TPMS sensor works properly, but also that the vehicle’s complete TPMS system functions properly as well. With the exception of some models that may be relearned to the vehicle via a driving procedure, a TPMS scan tool is required to complete the vehicle relearn procedure.

Sensor programming is an extra TPMS service step

Some aftermarket sensors require special programming to meet the vehicle’s application specifications prior to installation and relearn. These may include “programmable”, “universal” or “cloneable” sensors.

REDI-Sensor comes pre-programmed

Every replacement TPMS sensor must be “relearned” to the vehicle following the prescribed OE relearn procedure, regardless of whether it is an OE or aftermarket sensor. The relearn procedure ensures not only that the replacement TPMS sensor works properly, but also that the vehicle’s complete TPMS system functions properly as well. With the exception of some models that may be relearned to the vehicle via a driving procedure, a TPMS scan tool is required to complete the vehicle relearn procedure.